Additive Manufacturing inCommercial Aviation

Your localized supply chain optimization partner.

The global aerospace & defense additive manufacturing market, valued at $3.58 billion in 2020, is expected to rise to $13.01 billion by 2028, growing at a 19.51% CAGR. This market is highly influenced by the demand for lightweight components, rapid product development, and cost-effective parts in the aerospace supply chain. (https://www.fortunebusinessinsights.com/aerospace-defense-additive-manufacturing-market-106550).

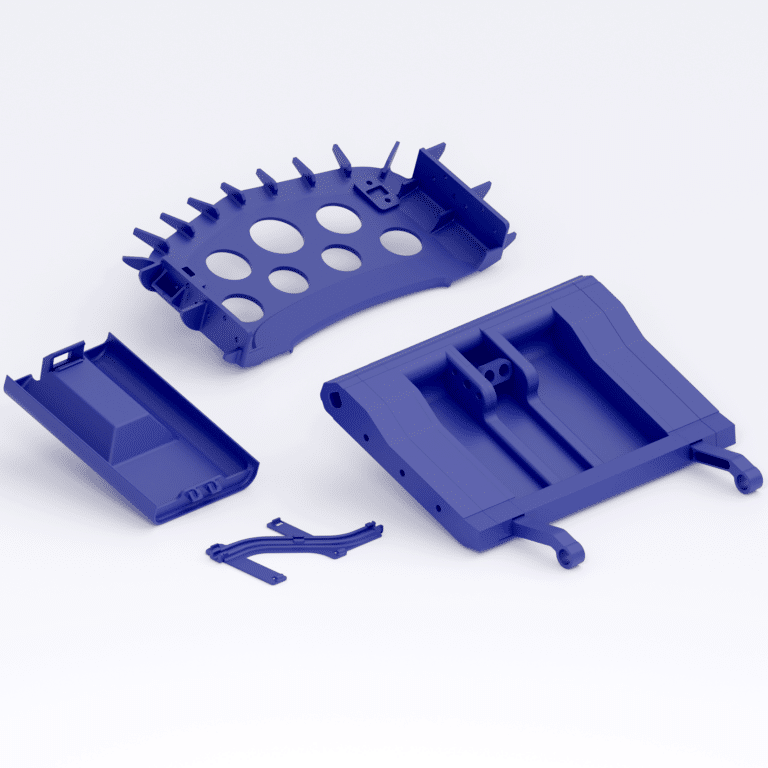

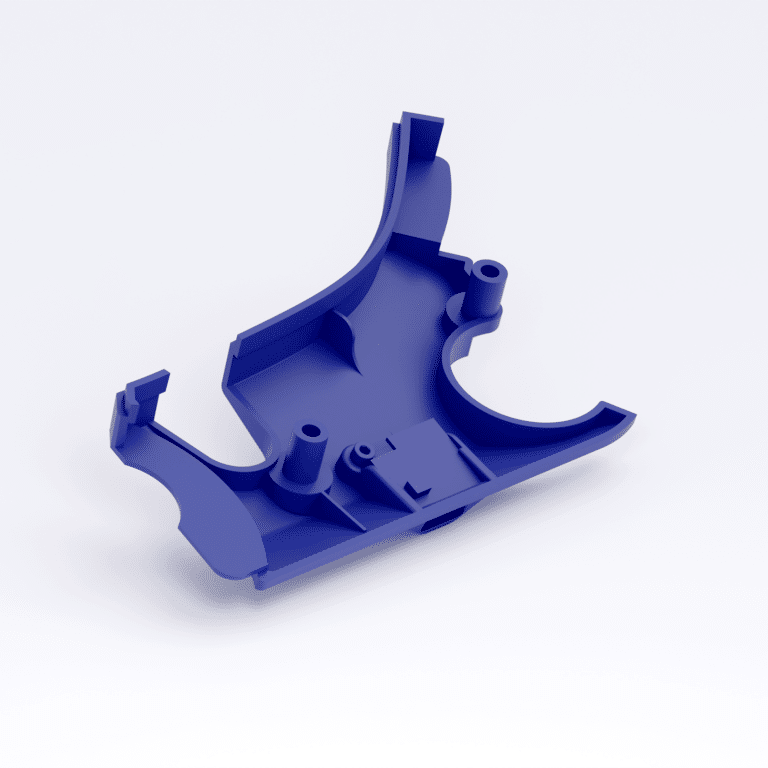

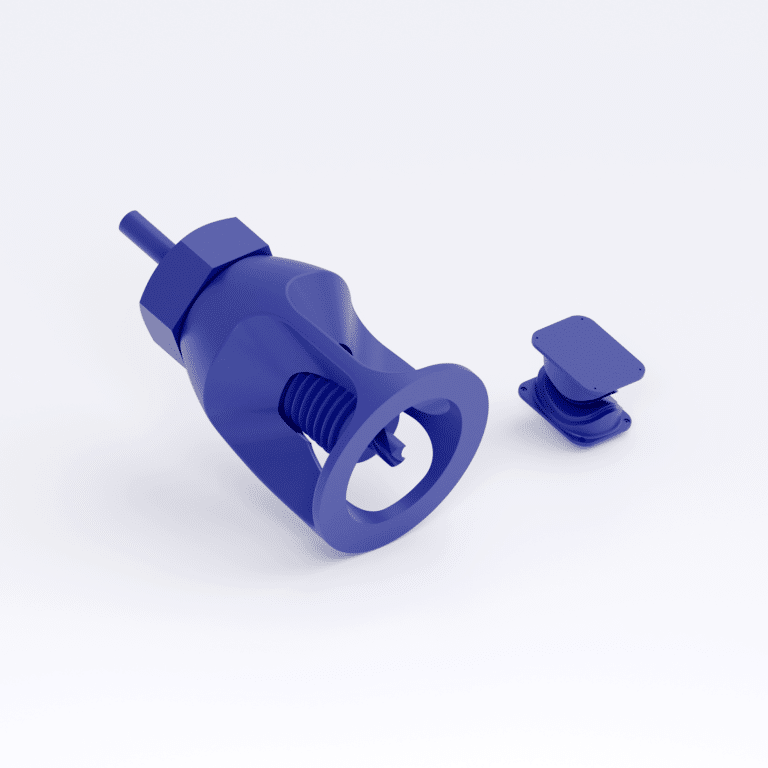

Rapid Prototyping: Streamline the design and development process by rapidly iterating and refining prototypes. With our on-demand digital manufacturing capabilities, you can significantly reduce time-to-market while gaining a competitive edge.

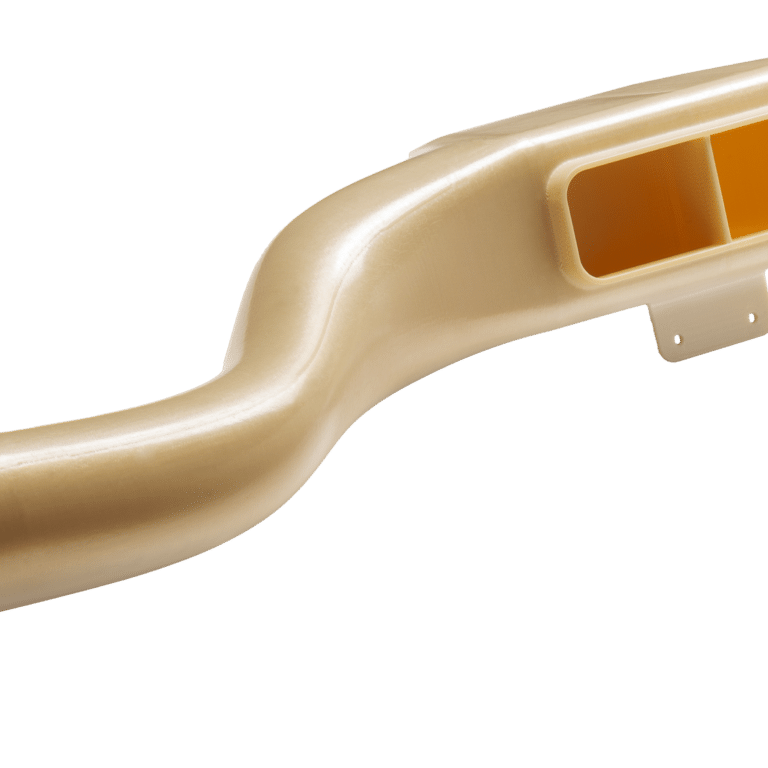

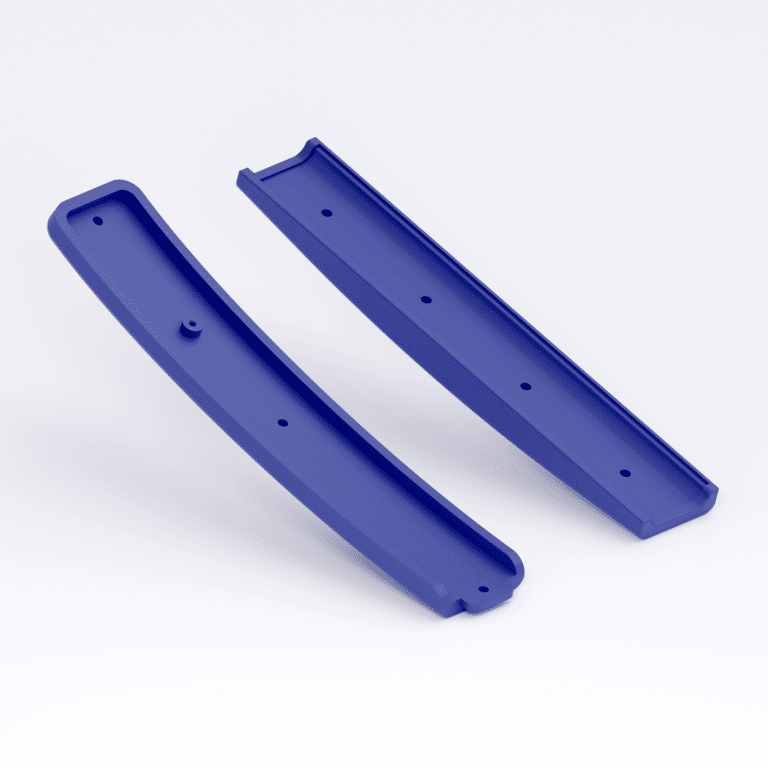

Customized Components: Address the growing demand for customization and personalization in commercial aviation. Our digital manufacturing solutions enable the creation of bespoke aircraft cabin components that perfectly meet your customers’ needs and enhance passenger experience.

Supply Chain Optimization: Minimize the risk of supply chain disruptions and reduce inventory costs. With our digital spare parts library, you can have critical components available on-demand, ensuring efficient just-in-time production without the need for large physical inventories.

Our unwavering commitment to impeccable quality ensures that every component we produce empowers the aviation sector to reach new heights both literally and figuratively. With Paradigm 3D, the aviation industry benefits from aircraft that are not only lighter and more efficient but also environmentally responsible.

- 1,100 parts per aircraft

- Almost 17.5M printable hours

- Servicing 1390 planes

- Addressable market for 3d printed parts estimated to be 1.0BN USD by 2032

- Targeting 0.2% of this market in 2023 and aiming to reach almost 2% by 2032.