Re-engineering of Labyrinth Cage in Additive Manufacturing (AM) for Oil & Gas Service

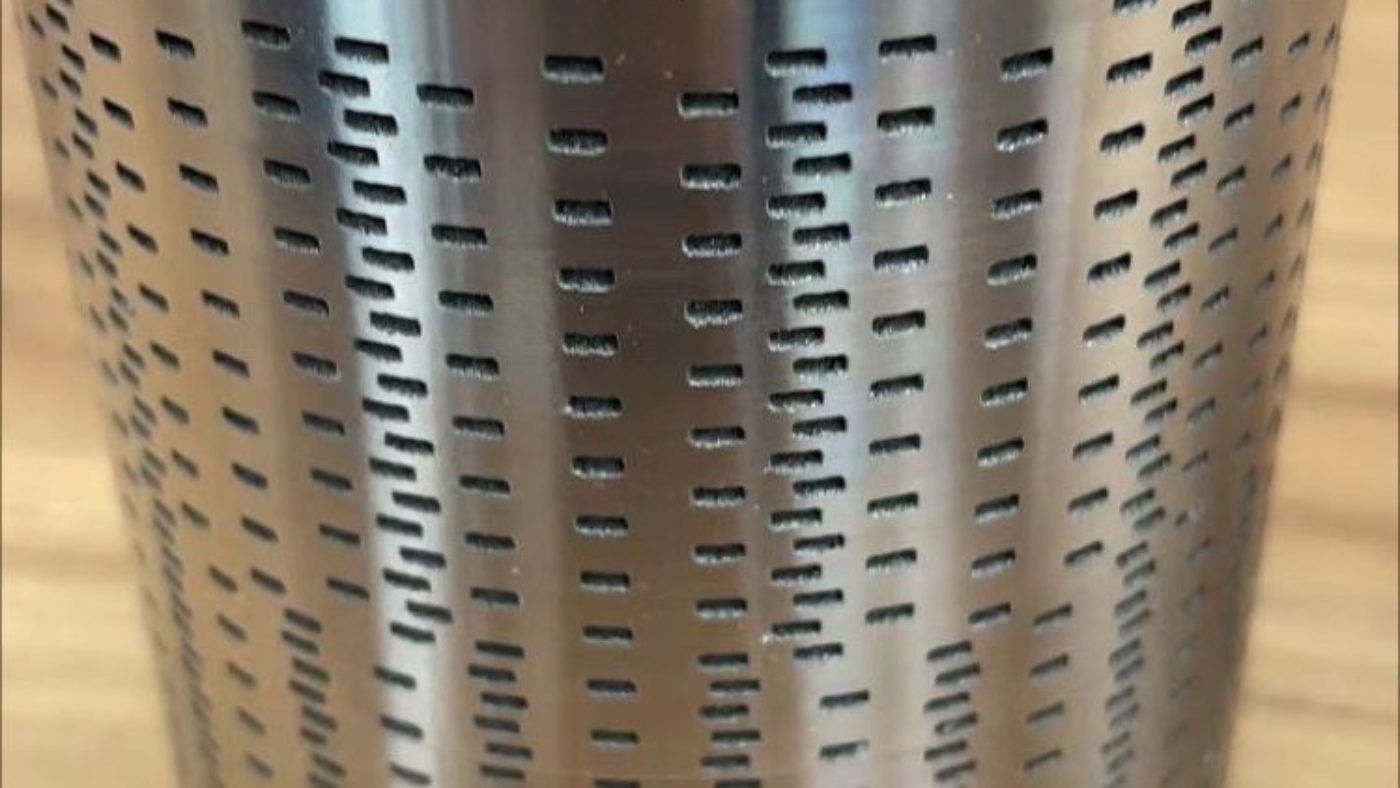

The team worked closely with the customer making precise measurements of the external dimensions of the old cage by a high-resolution 3D scanner, to ensure that after the manufacturing, the new part will fit perfectly in the valve. 3D Energy analyzed the process data and improved the design taking advantages of AM technology to include features not possible to have in traditional way. With the support of Paradigm3D, the complete cycle needed less than 3 weeks, from design to the 3D printed part, including test on specimens to guarantee quality. The customized & characterized labyrinth cage with high rangeability, precise control for all process conditions, cost 18% less than the traditional part. Now customer has the digitalized version of their part, repairable.

This case study was developed by us together with 3D Energy, our strategic consultant in Oil & Gas and our technology partner Eplus 3D.